Fillamentum Nylon PA12 CF15 black/natural

Fillamentum Nylon PA12 CF15 black/natural

Fillamentum Nylon (PA12) filament reinforced with 15 % of milled carbon fibers. It is characterized by high strength, high thermal and chemical resistance, great processing stability, and rheological properties. The objects are printed with high interlayer adhesion.

The functionality of objects is good under a wide range of temperatures.

The material is suitable for the production of continually stressed parts, such as bearings, cogwheels, reinforcement parts, etc. More

Manufacturer: FillamentumProduct code: 794 Shipping and Payment

Fillamentum Nylon (PA12) filament reinforced with 15 % of milled carbon fibers. It is characterized by high strength, high thermal and chemical resistance, great processing stability, and rheological properties. The objects are printed with high interlayer adhesion.

The functionality of objects is good under a wide range of temperatures.

The material is suitable for the production of continually stressed parts, such as bearings, cogwheels, reinforcement parts, etc. More

Manufacturer: FillamentumProduct code: 794 Shipping and Payment

Fillamentum Nylon CF15 is a Nylon based carbon fibres reinforced material for the FFF (also known as FDM) 3D printing technology.

It is characterized not only by high strength, rigidity and high thermal or chemical resistance, but also by great processing stability and rheological properties. The material properties are preserved also at low temperatures.

Thanks to the filler, this material excels by a low thermal expansion. It is suitable for printing of frequently stressed parts, for example bearings, cogwheels, reinforcement parts etc.

The use of the material in the food or medical industry is not recommended.

For filaments with fillers, Fillamentum guarantees dimensions within the tolerance +/- 0,10 mm, which are strictly controlled throughout production.

This material contains milled carbon fibres 100 Μm long.

Note

The Nylon CF15 filament has abrasive properties. It means that it will accelerate the nozzle-wear of brass nozzles faster than unfilled filaments. The hardened steel nozzles are recommended.

Features

- Mechanical properties retained also under low temperatures

- Wear resistance

- Suitable for printing continually stressed parts

- Stiffness & strength

- Creep resistance (resistance against deformation under long-term load)

- Great temperature resistance

- High hardness

- Nice & smooth surface

- Low density

- Chemical resistance against wide range of substances

- Improved tensile strength

- Low thermal expansion

- Safe to use in electrical and electronic equipment

Print settings suggested by manufacturer

- Printing temperature: 235 - 260 °C

- Heated bed temperature: 80-110 °C

- Speed: 35 - 50 mm/s

- Part cooling fant: 0%

- Heated bed surface: mirror/glass, garolite G10/G11, PEI

- Adhesive: Magigoo PA, glue stick, 3Dlack, PVAGlue

- Raft / skirt / brim: brim > 10mm

- Heated chamber / enclosure: required

Recommended settings!

It may differ according to the printer and the object.

Try your own settings before printing.

Adhesion

It is recommended to use large brim around the printed object. The best results were achieved with combination of glass bed and PVA glue. Magigoo PA also works fine. Nylons usually don’t stick to PEI well, but it is possible to print small rounded parts on PEI.

Cooling

It’s necessary to turn off the part cooling fan. Too high part cooling fan speed or too fast cooling of the printed object can lead to warp/shrink.

Storing

Airtight bag with desiccant.

In case of moist material, re-dry it in appropriate device. The conditions to achieve optimal level of moisture are 80 °C for 3 hours. Processing of moist filament may cause degradation of polymer chains, brittleness, poor layer adhesion, stringing, oozing etc.

Printed parts

If it’s possible at construction, avoid sharp corners touching the build plate. It could increase the warping effect when printing nylon.

Nozzle

It is highly recommended to use wear-resistant nozzles (Dexdo nozzle, hardened steel, ruby etc.), because of carbon fibers.

Technical information

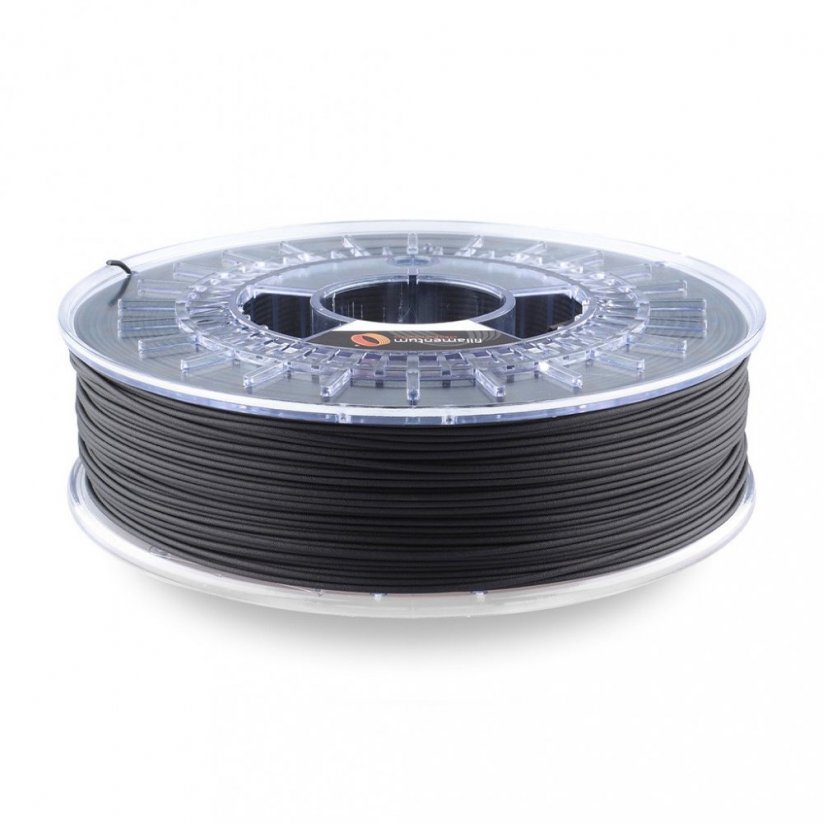

- Material: polyamide 12 (PA12)

- Color: natural/black

- Diameter: 1,75 mm

- Weight: 600 g

- Diameter tolerance: +/- 0.1 mm

- Melting temperature: 160 °C

- Hardness: 75R

Fillamentum products comparison

| Nylon AF80 Aramid | Nylon CF15 | Carbon Nylon FX256 | |

|---|---|---|---|

| Tensile strength | 50.4 MPa | 54.5 MPa | 45 MPa |

| Elongation on break | 5.8 % | 103 % | 50 % |

| Impact resistance | 53.2 kj/m2 (unnotched) ★ | 6.2 kJ/m2 (unnotched) ★ | 7 kJ/m2 ★★★ |

| Ease of printing | ★★★ | ★★ | ★ |

| Wear resistance | ★★★ | ★★★ | ★★ |

| Creep resistance | ★★★ | ★★★ | ★ |

| Heat resistance | from -40 °C up to 140 °C | from -40 °C up to 140 °C | from -40 °C up to 140 °C |

| Heat resistance at high load | ★★★★ | ★★★ | ★ |

| Color | |

|---|---|

| Manufacturer | Fillamentum |

| Filament weight | 0,6 kg |

| Filament material | Nylon (PA)|PA12 |

| Compatible with AMS | Yes |

| Compatible with AMS Lite | Yes |

| Country of origin | Czech Republic |

| Filament diameter | 1,75 mm |

| Heated bed temperature | 80 - 105 °C |

| Hotend temperature | 235 - 260 °C |

| Diameter tolerance | ± 0,1 mm |

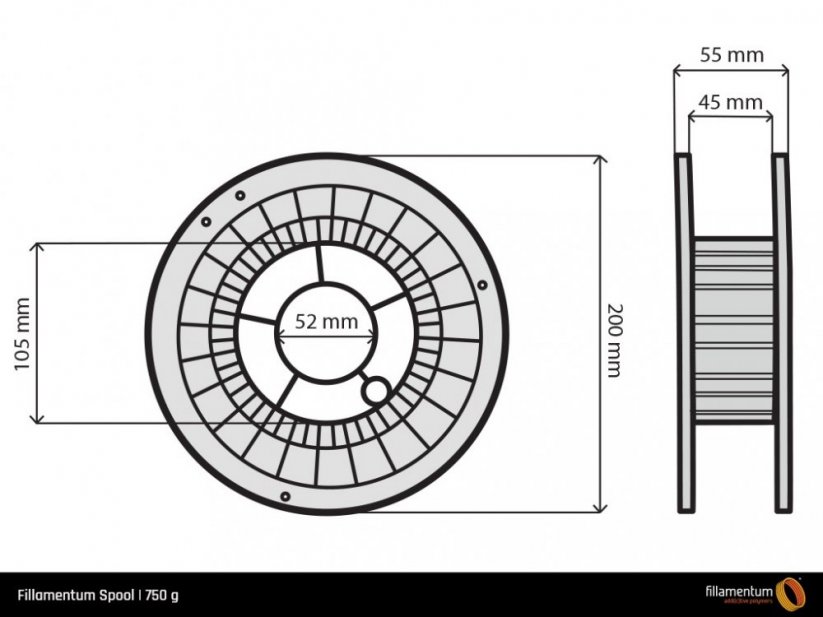

| Spool diameter | 200 mm |

| Material surface | Glossy |

| Spool width | 55 mm |

| Spool hole diameter | 52 mm |

| Closed chamber | Required |

| Hardness | 75D |

| Difficulty of printing | Expert |

| Drying conditions | 80 °C / 2-3h |

| Melting temperature | 160 °C |

| Length of filament | 243 m |