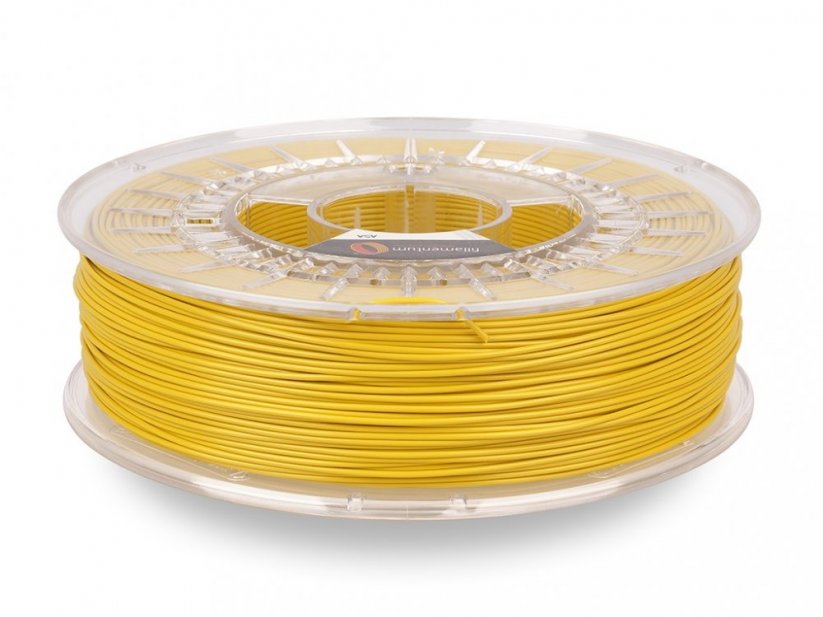

Fillamentum Extrafill ASA dijon mustard (yellow)

Fillamentum Extrafill ASA dijon mustard (yellow)

ASA is a styrenic polymer that is ideal for the production of the first functional samples before serial production for functional prototyping, manufacturing tools, but also for the production of goods for everyday usage, especially for outdoor applications.

It can withstand high long-term heat exposure and exposure to UV light. More

Manufacturer: FillamentumProduct code: 787 Shipping and Payment

ASA is a styrenic polymer that is ideal for the production of the first functional samples before serial production for functional prototyping, manufacturing tools, but also for the production of goods for everyday usage, especially for outdoor applications.

It can withstand high long-term heat exposure and exposure to UV light. More

Manufacturer: FillamentumProduct code: 787 Shipping and Payment

Thanks to mechanical properties is ASA filament ideal for the production of the first samples before serial production for functional prototyping, manufacturing tools, but also for the production of goods for everyday usage including outdoor applications.

The advantage of this material is its excellent weather resistance, high reten-tion of physical features and low level of yellowing.

ASA has a higher rigidity than ABS and thus it is suitable for demanding applications. Another advantage is its good dimensional stability.

This material can be used for production of electrical and electronic equipment. It doesn’t contain the restricted substances. The use of the material in the food or medical industry is not recommended.

Fillamentum guarantees precision of filament dimensions within the tolerance of +/- 0,05 mm, which is strictly controlled throughout the production.

Features:

- Low levels of yellowing

- Excellent weather and UV light resistance

- Retention of physical features such as color and mechanical properties

- Low moisture absorption

- Impact resistance

- Higher resilience than ABS

- Recyclable

- Chemical resistance against alkalis, alcohols, oils, greases, ozone, and water

- Long-term dimensional stability

- Low density

- Safe to use in electrical and electronic equipment

Print settings suggested by manufacturer

- Printing temperature: 240 - 255 °C

- Heated bed temperature: 80-105 °C

- Speed: 30 - 50 mm/s

- Part cooling fan: 0 - 20 % (5% is a good start)

- Heated bed surface: PEI, mirror/glass

- Adhesive: Dimafix, PVA glue, 3DLac, Magigoo

- Raft / skirt / brim: Brim 5-10 mm

- Heated chamber / enclosure: recommended

Cooling

It is not recommended to use more than 20 % of fan speed, as too much cooling could lead to improper layer bonding and warping. We recommend using no cooling for standard objects, which leads to stronger parts. For bridges and big overhangs, it is possible to go up to 30–40 % for the desired layer.

Adhesion

Brim 5 – 10 mm. The best adhesion was achieved with Dimafix on clean glass or mirror. On the PEI we recommend using wider brim for large objects.

Overhangs

For the overhangs higher than 45° we recommend using lower layer heights and also enough time to cool, otherwise, overhangs could slightly warp.

Note Hotend:

The manufacturer gives very conservative values. Cooling recommended for chamber printing 30-40% depending on cooling capacity (except for first layers), for bridges and overhangs cooling can be increased up to 60%. The speed is realistically limited more by the flow rate of the hotend used. When printing and specially on glass with Dimafix, brim is not necessary even for large prints.

Technical information

- Material: acrylonitrile-styrene-acrylate (ASA)

- Color: dijon mustard (yellow)

- Diameter: 1,75 mm

- Weight: 750 g

- Diameter tolerance: +/- 0.05 mm

- Heat resistance: 96 °C

- Vicat softening temperature: 94 °C

- Hardness: 92R

Comparison of styrenic polymers from Fillamentum

| PC/ABS | ASA Extrafill | ABS Extrafill | HIPS Extrafill | |

|---|---|---|---|---|

| Weather resistance | yellowing | UV stability | yellowing | yellowing |

| Tensile strength | 42 MPa | 40 MPa | 32 MPa | 26 MPa |

| Elongation at break | 7 % | 35 % | 20 % | 40 % |

| Hardness | ★ ★ ★ ★ | ★ ★ | ★ ★ ★ | ★ ★ |

| Impact resistance (notched) | ★ ★ ★ | ★ ★ ★ | ★ ★ | ★ ★ |

| Heat resistance (Vicat) | 113 °C | 94 °C | 96 °C | 88.5 °C |

| Color | Yellow|White |

|---|---|

| Manufacturer | Fillamentum |

| Filament weight | 0,75 Kg |

| Filament material | ASA |

| Compatible with AMS | Yes |

| Compatible with AMS Lite | Yes |

| Country of origin | Czech Republic |

| Filament diameter | 1,75 mm |

| Heated bed temperature | 90 - 105 °C |

| Hotend temperature | 240 - 255 °C |

| Diameter tolerance | ± 0,05 mm |

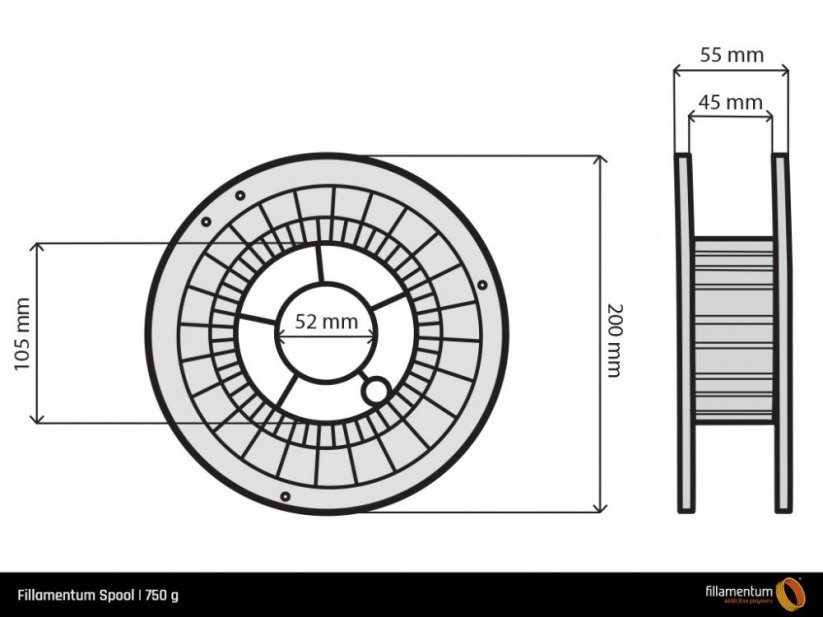

| Spool diameter | 200 mm |

| Material surface | Mat |

| Spool width | 55 mm |

| Spool hole diameter | 52 mm |

| Softening temperature | 94 °C |

| Closed chamber | Recommended |

| Hardness | 92R |

| Difficulty of printing | Advanced |

| Heat Distortion Temp | 96 °C |

| Length of filament | 310 m |